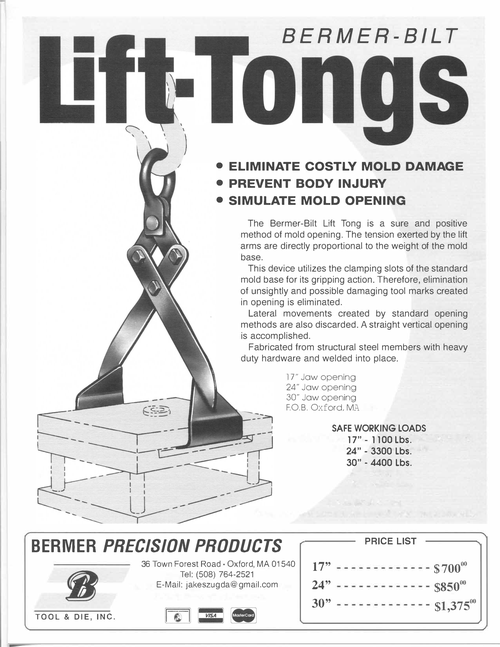

The advantages of the Tongs are:

- Eliminate damage to the mold since there is no lateral movement as in conventional opening method of prying mold halves with metal pry bars or screw drivers.

- Prevent rubbing and galling of guide pins, side actions, and core/cavities during separation and assembly of mold.

- Ability for a single person to open even a large or heavy mold with this device using an overhead crane, and prevention of potential bodily injury.

- Significant savings in time and labor.

- Payback on investment in a matter of months.

The Tongs are designed and built in the U.S., and fabricated from structural steel members with heavy duty hardware. The Tongs are available in 3 sizes, with weight capacity from 1100 to 4400 lbs.

The Tongs were first introduced in 1960, and thousands have been sold to many OEMs, toolmakers, and injection molders. Leading companies such as General Motors, 3M, Nypro, Black Decker, Tech Molding, etc. have been using them successfully for decades.

|